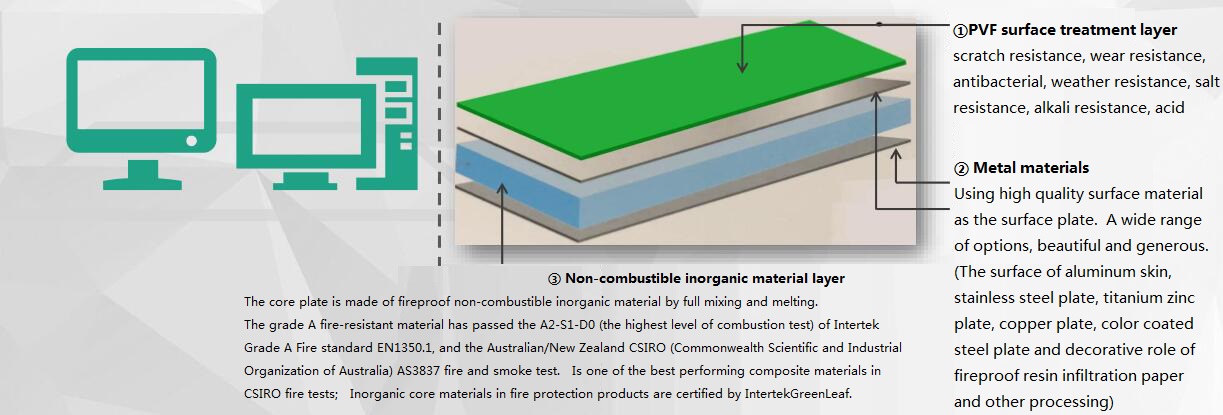

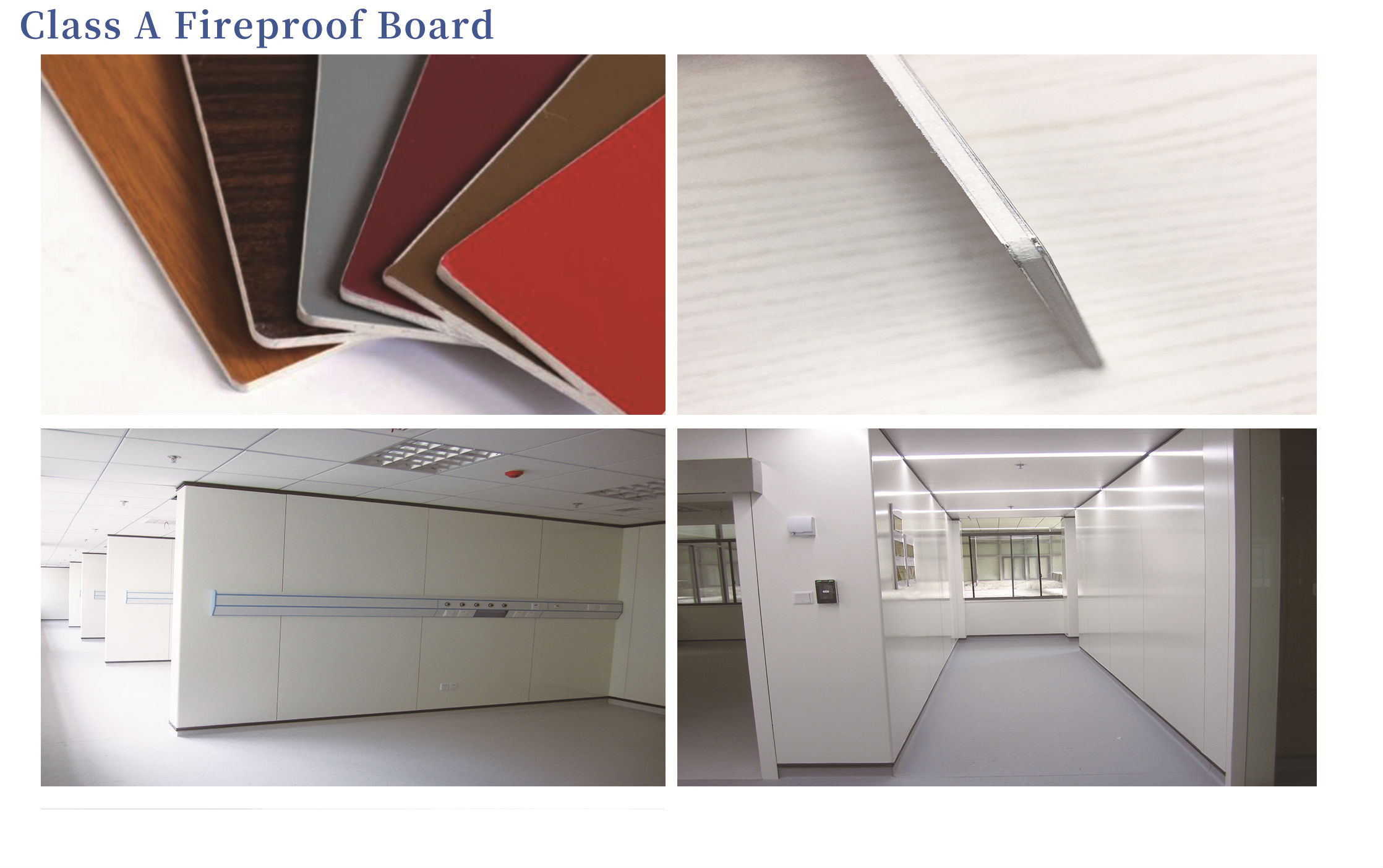

Grade A fireproof metal composite board is A kind of green, ecological refractory building materials. It adopts non-combustible inorganic material as the core material, and is composed of metal plates with fluorocarbon or polyester coating as a protective layer. With its fire resistance and physical properties, especially in the performance of fire rating and peeling strength, the product is widely used in various architectural decoration fields.

Metal material

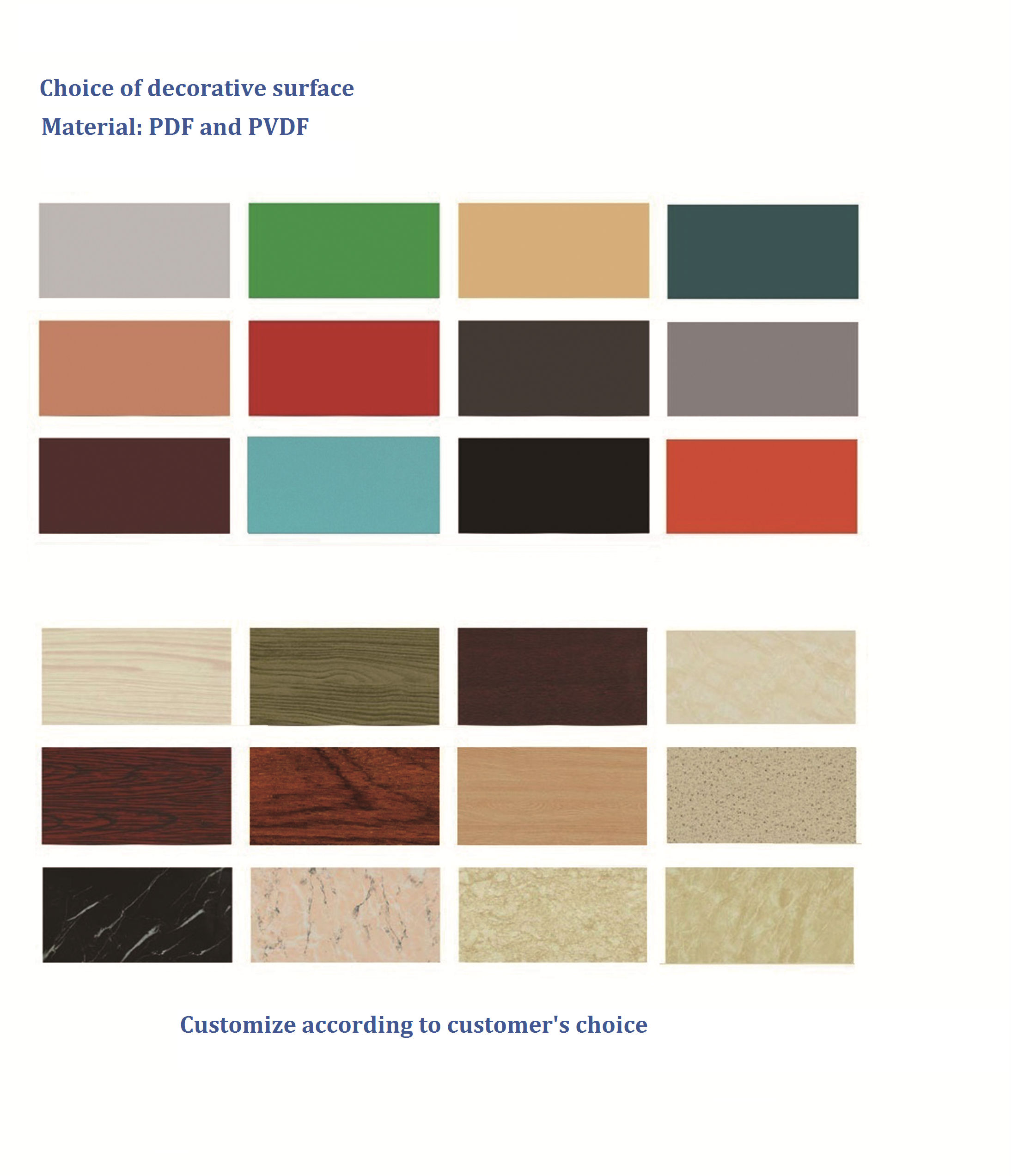

The surface plate can be selected from a wide range, beautiful and generous. (The surface of aluminum skin, stainless steel plate, titanium zinc plate, copper plate, color coated steel plate and decorative role of fireproof resin infiltration paper and other processing.)

Non- combustible inorganic material layer

The core plate is made of fireproof non-combustible inorganic material, which is fully mixed and fused.

The grade A fireproof material has passed the A2-S1-D0 of Intertek(Intertek) Grade A fireproof standard EN1350.1, and the Australian/New Zealand CSIRO(Australian Commonwealth Scientific and Industrial Research Organization) AS3837 fire and smoke control test; Inorganic core materials in fire protection products are certified by IntertekGreenLeaf.

The whole product has reached the national Fixed fire extinguishing System and Fire-resistant Components quality Supervision and Inspection Center according to GB8624-2012 "Building Materials and Products Combustion Performance Classification" grade A test standard;

Through the national Building Materials Supervision and Inspection Center of aluminum plastic composite board 27 full set of tests, the product's peel strength, temperature difference resistance, artificial climate aging resistance and other items of the test results are in line with GB/T17748-2008 "Aluminum plastic composite board for Building curtain wall" standard requirements;

According to the test of Intertek standard testing center of the International Union, the test results of the product meet the test requirements of grade A, en13501-1:2007 +A1:2009 and ASTMD1781-98 related requirements.

The standard specifications

Standard products

Sheet thickness 4mm

Sheet width 1220mm

Sheet length 2440mm

Aluminum skin thickness 0.5mm

Decorative coating PVDF

Non-standard products

Can be specially customized 3mm-5mm arbitrary thickness

Any width from 900mm to 1575mm can be customized

It can be customized to any length from 500mm to 11000mm

The surface aluminum skin can be selected from 0.12-0.48mm

The coating can be PE or coated with nano self-cleaning paint

1 Installation Direction

Due to general grade A fireproof paint film on the surface of the composite board is made of roller coating process, coating color may have A certain direction (especially metallic), from A different perspective, A grade fire composite board sense color may have certain differences, in order to avoid this kind of difference, class A fire retardant composite panels shall be installed according to the direction of the same production.

2 Cleaning and maintenance

Grade A fireproof composite board should be cleaned and maintained at least once A year to remove surface stains and harmful substances, so as to keep the board clean and ensure the normal service life of the product. Neutral cleaning agent should be used for flexible cleaning. Before cleaning, it should be considered whether the cleaning agent has adverse effects on the coating of grade A fireproof composite board.

3 Storage conditions

Class A fireproof composite panels should be stored in A dry, cool, ventilated and flat place, and the storage temperature should not exceed 70℃.

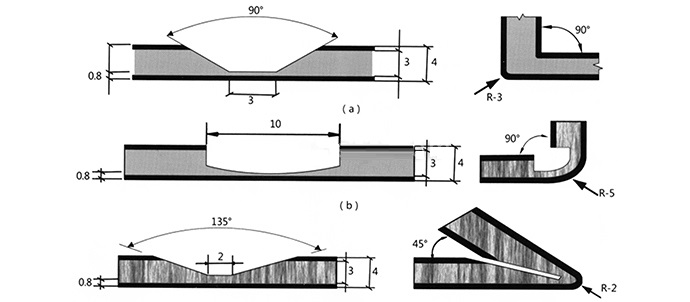

4 Hem and bend

For the application of slotted flanging of grade A fireproof composite board, the flanging procedure should be considered in advance, and repeated flanging should not be carried out; The minimum bending radius should not be less than 750px for class A fireproof composite boards that need to be directly bent without slotting.

5 Matching sealing materials

The sealing material used for class A fireproof composite panels shall have good weather resistance and good compatibility with class A fireproof composite panels. Sealing materials should also meet the corresponding national or industrial standards. Because inferior sealing materials can contaminate and even corrodes Class A fire resistant composite boards, it is necessary to test for the compatibility of sealing materials with class A fire resistant composite boards in advance.

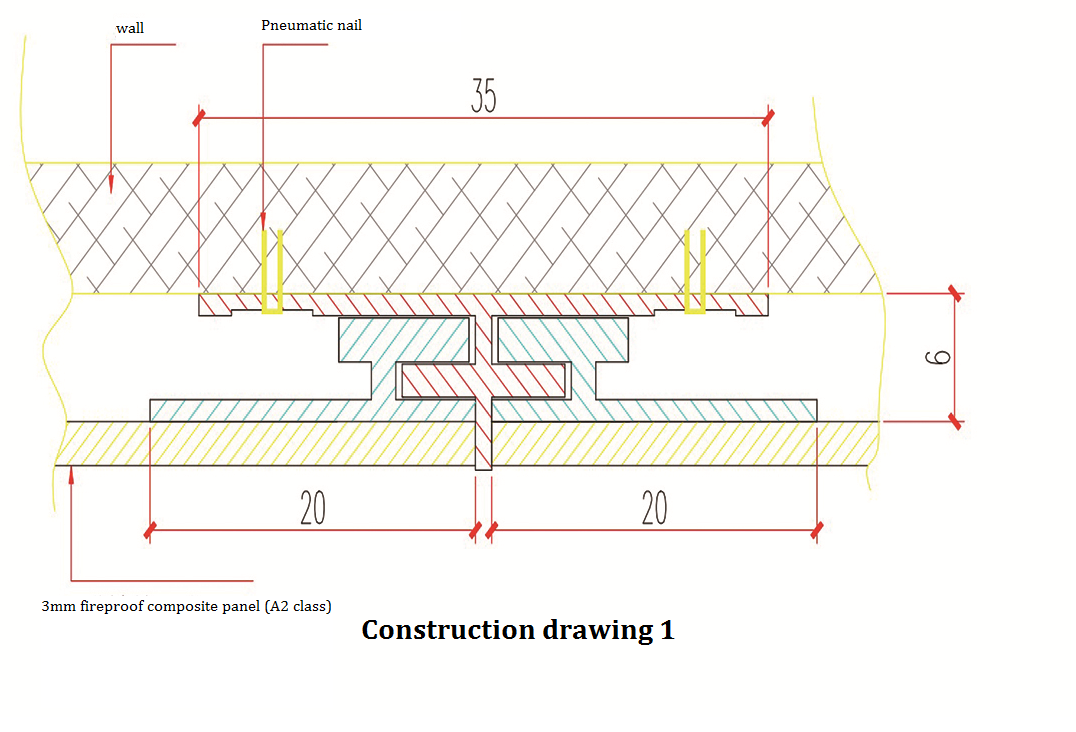

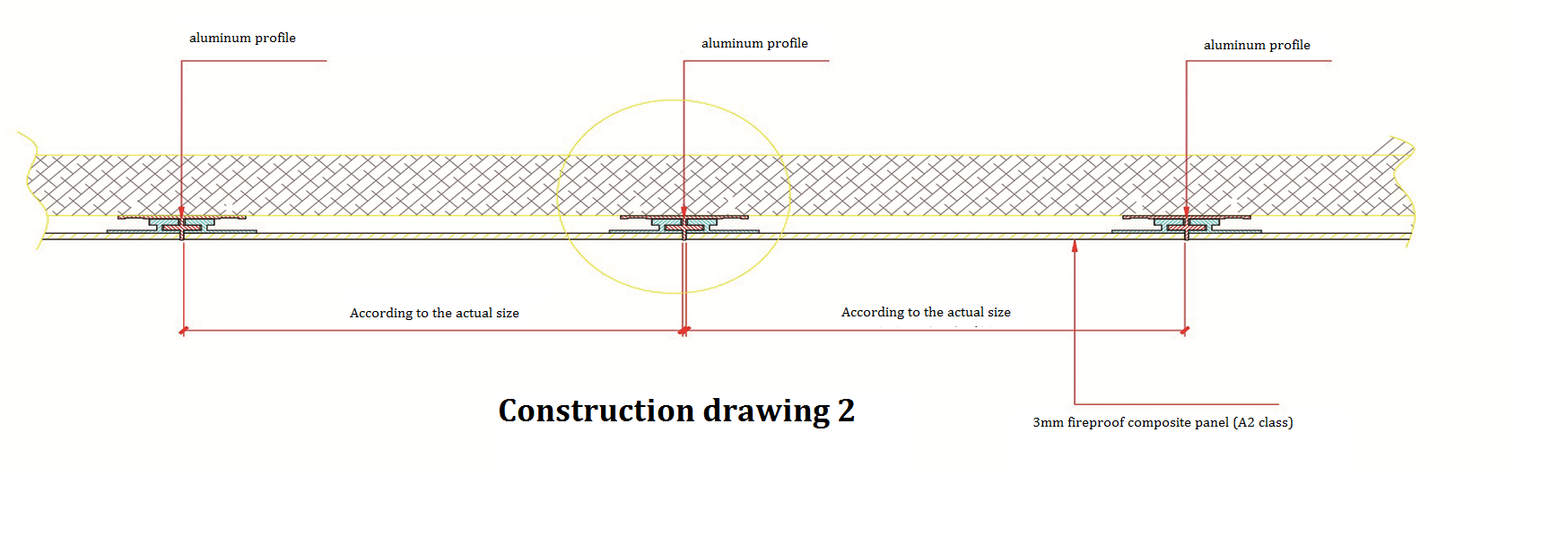

6 Design and Installation

The design and installation of grade A fireproof composite board should implement the relevant design and installation specifications, and fully consider the possibility of thermal expansion and cold contraction, in order to avoid the adverse impact on the project and the flatness of the board.

7 transport

In the process of handling and transportation, grade A fireproof composite panels should be placed flat, tidy and stable, avoiding shifting, dragging, scratching the surface, collision and local compression injury.